Design considerations for an assembler

by

Ralph C. Merkle

Xerox PARC

3333 Coyote Hill Road

Palo Alto, CA 94304

merkle@xerox.com

www.ralphmerkle.com

Copyright 1995 by Xerox Corporation. All Rights Reserved.

This paper was presented at the Fourth Foresight Conference on Molecular Nanotechnology. The final version was published in Nanotechnology 7 (1996) pages 210-215. This web version differ in some respects from the published version.

This paper is available on the web at http://www.zyvex.com/nanotech/nano4/merklePaper.html

WARNING: This page uses the <sup> and <sub> convention for superscripts and subscripts. If "103" is the same as "103" then your browser does not support superscripts. If "xi" is the same as "xi" then your browser does not support subscripts. Failure to support superscripts or subscripts can lead to confusion in the following text, particularly in interpreting exponents.

Abstract

Assemblers have been proposed as general purpose manufacturing devices, able to build a wide range of useful products as well as copies of themselves. If such systems are to be built they must first be designed; and before they can be designed in detail we need to know at the system level what major subsystems are needed, what functions they perform, and how they interact with each other. This paper attempts to fill this need and describes the subsystems and components required for a relatively "simple" assembler.Introduction

It is now widely believed that nanotechnology (see http://www.zyvex.com/nano) is feasible and will likely be developed in the coming decades. However, there is still significant uncertainty about what molecular manufacturing systems might look like and even greater uncertainty about how best to proceed in developing such systems. This uncertainty is not aided by the fact that many different development pathways are likely to work, and that to a significant extent the selection of a specific pathway is arbitrary. Further, as our present vantage point suggests that all pathways will require at least a few major stages, the analysis of the advantages and disadvantages of alternative paths is rendered complex. We try to reduce this complexity by outlining a "simple" molecular manufacturing system.The direct manufacture of this "simple" system with current technology seems unlikely to be feasible. As a consequence, it will probably be necessary to develop other systems that are easier to synthesize using today's methods, but which are sufficiently powerful that we can use them to synthesize more sophisticated systems. This might be likened to the ascent of a tall mountain in stages, with base camps established at intermediate elevations. The precise nature of these intermediate stages depends on the design of the final stage. The present proposal might be likened to a final base camp, close enough to the peak that it's clear that a final assault from this final base camp would reach the peak, but far enough removed that it's significantly easier to reach the base camp than the peak.

A present guess about what a mature molecular manufacturing system might look like is some form of convergent assembly system (Merkle, 1997a). It should be possible to manufacture such a system given the capabilities of the simple diamondoid assembler described here. We do not propose the construction of a convergent assembly system directly because it would be significantly more complex and would need significantly more resources to complete.

What is nanotechnology?

The term nanotechnology is often used to refer to almost any technology where some characteristic dimension is smaller than a micron. By contrast, the usage in this paper refers specifically to molecular nanotechnology, a.k.a. molecular manufacturing. The basic thesis of this field is that most structures consistent with physical and chemical law can be manufactured inexpensively. This possibility was first mentioned by Feynman in a visionary talk in 1959 (Feynman,1960). More recently, it has been the subject of considerably more detailed analysis in Nanosystems (Drexler, 1992).Current proposals for molecular manufacturing systems revolve around two central concepts: positional control (Merkle, 1993) and self replication (Merkle, 1992). At the macroscopic scale, the idea of using positional control as part of the manufacturing process is not only quite natural it is hard to imagine a modern factory without it. Parts are moved from place to place by conveyor belts, robotic arms, human arms, and a variety of other contrivances. After being positioned appropriately with respect to each other they are then bonded, glued, soldered, screwed, clamped, hooked or otherwise connected to each other. The resulting assemblage of parts is then moved along and usually connected to other parts.

At the molecular scale, the most common method of assembling parts is some form of self assembly. Molecular parts (in test tubes) are stirred together and allowed to gyrate, bump, jostle and bang into each other under the influence of thermal noise. By exercising great ingenuity, chemists are routinely able to synthesize a remarkably wide range of small molecular structures without the molecular equivalent of hands: the parts spontaneously arrange themselves in the desired pattern. It seems intuitively plausible that adding positional control at the molecular level should enable the synthesis of a much broader range of structures than is now feasible.

Positional control at the molecular scale is, however, a new concept that has yet to be fully accepted. While experimental successes (Eigler and Schweizer, 1990) clearly demonstrate that positioning molecular parts does not violate any fundamental laws of nature, such successes are today limited to specific systems. Perhaps the clearest support for the idea that more general capabilities are feasible comes from ab initio and molecular mechanics modeling of specific reactions that should prove useful in the synthesis of desired structures. See, for example, Theoretical studies of a hydrogen abstraction tool for nanotechnology (Musgrave et al., 1991) or Surface patterning by atomically-controlled chemical forces: molecular dynamics simulations (Sinnott et al., 1994), as well as the discussion of mechanosynthesis in Nanosystems (Drexler, 1992).

We shall assume, for the remainder of this article, that molecular positional control is an essential prerequisite for molecular manufacturing.

Self replication

The second central concept on which current proposals for molecular manufacturing are based is that of self replication. The utility of this is fairly obvious: it lets us make things inexpensively. While the addition of positional control to our manufacturing methods should let us build a much wider range of structures than could otherwise be considered, the manufacture of a few molecular sized components will not, by itself, greatly alter the economics of the world's manufacturing base. If we are to build macroscopic structures which are molecular in precision using positional control to position and assemble molecular size components, we will need mole quantities of positional devices. This has two implications: the devices themselves will have to be small, and their manufacture will have to be completely automated (human intervention in the manufacture of each of a mole of devices seems implausibly labor intensive given the present population).A conceptually simple way of meeting these requirements is to embody the needed capabilities in a self replicating device called an assembler, which has one or more positional devices controlled by a small general purpose computer. As the assembler can make copies of itself (the author does work at Xerox) a single assembler can manufacture a second, those two can make two more, those four can make four more, etc. Exponential growth allows the rapid manufacture of as many assemblers as might be desired, while the fact that they are under computer control permits them to be reprogrammed to build other structures that are deemed useful (molecular computers, for example).

Although we have elevated the concept of self replication to the status of a central principle, it would be incorrect to assume that self replication, in and of itself, is valuable. A device able to make copies of itself but which was unable to make anything else (and was otherwise of no particular value) would be of no great value. The value of the assembler rests fundamentally on its ability to make a great many different things under programmatic control. Self replication is used as a method of achieving economy in the manufacturing process, not as an end in itself.

Design objectives

As there are a great many possible assemblers, and as their characterisics vary considerably, it is necessary to provide some context for the particular design approach selected here.First, we seek a design which fairly obviously will let us build a reasonably broad range of useful products, including more sophisticated assemblers. We do not demand that the proposed design be able to directly manufacture the full range of products which might be desirable, but will instead restrict ourselves to the class of "diamondoid" structures, defined in Nanosystems (Drexler, 1992) as including structures made from hydrogen; first row elements such as boron, carbon, nitrogen, oxygen and fluorine; and perhaps some second row elements such as silicon, phosphorous, sulfur and chlorine. Metals and other elements will generally (though not always) be excluded from consideration. We will frequently confine ourselves to hydrogen and carbon, as hydrocarbon structures are relatively easy to analyze and can often provide remarkable materials properties (e.g., diamond, graphite, and related structures). Potential energy functions which provide a good description of the behavior of hydrocarbons are available. Brenner's potential (Brenner, 1990) is an example. It is able to model not only relatively stable structures, but also transition states and less stable structures. The utility of this potential for modeling a wide variety of hydrocarbon-based molecular machines and synthetic reactions has been noted by Brenner (Brenner et al., 1996). One example available on the web is the work of Robertson (Robertson et al., 1994), who did molecular dynamics simulations of molecular gears (available at http://chem.iupui.edu/Chem/Research/Robertson/Roberston.html).

The restriction to diamodoid structures has two major advantages. First, these structures have some of the most desirable materials properties known. They involve strong covalent bonds, and hence include the strongest and stiffest materials. Their other materials properties -- chemical, thermal, electrical, optical etc. -- are also remarkable. Second, their behavior (particularly when we confine ourselves to relatively simple structures) is easier to understand and analyze.

We will further restrict ourselves to the class of "small" diamondoid structures, e.g., structures which are about the same size as the proposed assembler.

We choose the broadcast architecture. In this architecture, the assembler does not have an on-board computer, but is instead directed by simple broadcast instructions. This architecture is similar to the "SIMD" architecture used in some massively parallel computers. A central computational element (macroscopic) broadcasts simple instructions to a large number of assemblers. The assemblers are barely able to decode and execute these simple instructions, thus reducing their complexity and size.

Several things must be described if we are to specify an assembler, as discussed in (Merkle, 1992). For this proposal, we will use:

- The

double

tripod (Merkle, 1997c). This is a relatively compact, six degrees

of freedom positional

device which combines high stiffness with a wide range of motion.

- To allow the synthesis of diamondoid structures, we will use

molecular tools with highly reactive tips (Merkle, 1993).

These reactive tips

will include radicals, carbenes, and other highly reactive species

of the general type

found today in the CVD synthesis of diamond. Some

proposals for reactive tips are:

- The use of highly reactive compounds as molecular tools implies

that the internal environment of the assembler must be inert.

We select compressed neon. While vacuum is also inert, as will be

made clear later we require an internal medium that is able to carry

acoustic (pressure) signals. Helium is an attractive alternative

and should also work. As the design might use sliding

seals which should block diffusion of the inert gas (useful

for the design of pressure actuated ratchets and pistons --

though bellows,

which have no sliding seals at all, are also feasible) it is

convenient to select the slightly larger inert gas. While sliding

seals that block the passage of helium should be feasible, they

must be tighter and present a greater design challenge.

- The internal transport of molecular tools and other components

will be done by the double tripod positional device, mentioned above.

This "pick and place" approach is not the most efficient, but simplifies

the design. Note that within the shell of the assembler, the location

of every structural atom is known to within the uncertainty created by

thermal noise (positional uncertainty caused by

quantum effects is

smaller than uncertainty caused by thermal noise for the conditions

considered here (Drexler, 1992, figure 5.2)).

As the internal structural components have relatively

high stiffness, the positional uncertainty caused by thermal noise is

small. The basic equation relating temperature to thermally induced

uncertainty in position in one dimension is:

-

positional variance = kT/ks

At room temperature, kT is approximately 4 x 10-21 joules. A reasonable value for ks is 10 newtons/meter. The resulting variance in position is 4 x 10-22 meters2, leading to a standard deviation in position of 2 x 10-11 meters or 0.02 nanometers.

In short, provided that reasonably stiff structural elements are used, the position of every structural atom in the system can be known to within a fraction of an atomic diameter with high reliability at room temperature and without the need for explicit positional sensing. This approach might be likened to a blind man assembling a product at a workbench where every tool and every component had a known position -- the blindman would be able to perform the assembly operations despite the absence of positional sensing capabilities because the location of every nut and bolt was known.

While this approach requires that the positional device have very good absolute positional accuracy, the positional device is itself molecular in precision. Therefore there will be no structural errors in the positional device to cause wear or other unpredictable sources of positional uncertainty. Thermal noise will be the only significant contributor to positional uncertainty, and by designing a system that is sufficiently stiff this can be reduced to acceptable levels.

- To isolate the internal environment from the external environment,

we will use a diamondoid wall. Much of this wall could be graphitic,

as this is both thin and should be sufficient to prevent the entry of

unwanted contaminants from the external environment.

- The external environment will be liquid. Several candidates are

possible including water, a suitable hydrocarbon (e.g., hexane), or

a wide range of others. A major factor in determination of the

liquid external environment is the need to dissolve the feedstock

molecules in it. As the design of these molecules has not yet

been specified, the selection of the external liquid environment

is also not specified.

- While feedstock molecules could be transported from the exterior of the

assembler to the interior using multiple stages of variable

affinity binding sites (one of which is depicted in the following figure from

Nanosystems (Drexler, 1992)) simpler but less general alternatives are

explored in (Merkle, 1997b).

- Broadcast signals will be transmitted from the central (macroscopic)

computer control system to the assemblers by acoustic waves. These

will be carried outside the assemblers by the liquid in which they

are immersed, and inside each assembler by the compressed neon

used as the internal environment.

- Each degree of freedom of the double

tripod will be controlled by

a suitable threshold pressure actuated rachet. These ratchets

will be operated by using pressure actuated pistons.

A design using a constant force spring is relatively compact. Once the external pressure exceeds the threshold, the piston will move to the left by its full throw.

An alternative design is:

The pressure threshold in this design is adjusted simply by altering the pressure of the confined gas. By contrast, the threshold in the constant force spring is adjusted by small shifts in the diameter of the internal shaft and external sleeve -- which makes the threshold more sensitive to the precise details of the potential energy function, and in particular the repulsive van der Waals interaction between the shaft and sleeve. The use of compressed gas in the second design makes it less sensitive to the details of the potential energy function.

Unfortunately, these advantages are purchased at a cost: the use of compressed gas results in a larger piston and reduces its sensitivity to changes in external pressure. In particular, when the external pressure is increased the volume of the confined gas is decreased by the piston, and hence its pressure increases. This implies that a larger change in external pressure is required to move the piston the same distance. While this can be compensated by increasing the total volume of the confined gas, (and hence decreasing the relative change in volume caused by movement of the piston a specific distance), it will cause a further increase in the size of the piston.

If the piston in the first design has a working volume of 125 cubic nanometers, then a pressure change of 3.2 x 106 Pascals (about 32 atmospheres) would permit the piston to generate 4 x 10-19 joules (2.5 electron volts, 58 kilocalories/mole). This means that forcing the piston to the "wrong" end of its throw will require an amount of energy much greater than thermal noise. In consequence, reliable operation, even in the face of thermal noise at room temperature, is feasible when the piston size is on the order of 100 cubic nanometers.

Qualitatively similar but numerically somewhat different results hold for the second design.

Different ratchets could have different activation pressures, and so by adjusting the static pressure to the threshold value of a specific ratchet, and then varying the pressure to just above and just below the threshold, the specific ratchet can be activated. Nanosystems (Drexler, 1992) discusses pressure actuated ratchet mechanisms and the fundamental issues surrounding reliable ratchet operation in the face of thermal noise.

We adopt a variant of the pressure actuated ratchets proposed in Nanosystems that provides somewhat greater flexibility in addressing individual ratchets. In particular, we will adopt a "two band" signaling model. That is, instead of adressing each individual ratchet by assigning it its own pressure range, we use pairs of ratchets and use only two pressure ranges. The first pressure range activates the first of the pair of ratchets, which we will call stepping ratchets, and causes a circular band to be stepped forwards. At one or more points on the circular band are notches that indicate that the second of the pair of ratchets is to be made active. Each pair of ratchets has a unique set of notches in its associated circular stepping band. The second ratchets we will call working ratchets: they control the actual activities of the assembler. All working ratchets are either active or inactive, depending on the presence or absence of a notch in the stepping band. Signals sent in the second pressure range cause the active working ratchets to step but have no effect on the inactive working ratchets. By this method an indefinite number of working ratchets can be made active or inactive, and in fact can be made active and inactive in sets (if that should prove useful). We might, for example, arrange matters so that all working ratchets that extend their respective struts could be made active at the same time, permitting the more rapid extension of the double tripod.

The price we pay for this mechanism is the need to send stepper signals to activate the stepper ratchets and so select which working ratchets are to be active. While this will somewhat slow the signaling process, it has the distinct advantage over the original proposal in Nanosystems that the addition of new working ratchets will not require an extension in the pressure range of the system. Thus, new working ratchets can be readily added late in the design or implementation cycle with minimal bother. In addition, the total pressure range that the system must accomodate is made much smaller, simplifying both the pressure control mechanisms and the design of the pressure actuated ratchets (the amount of overpressure that a ratchet is required to tolerate is greatly reduced, for example).

As the pressure actuated ratchets are inside the assembler and the source of the pressure changes is outside, we must insure that pressure changes are transmitted with reasonable accuracy from the outside to the inside. A piston at the end of the assembler (see the final illustration in this article showing the "simple" diamondoid assembler) is one method for insuring equilibration of pressure inside and outside the assembler. As the external pressure is varied the piston slides back and forth, transmitting pressure changes from the outside of the assembler to the inside.

Bellows would also work, and would have the advantage that they could be more compact in the collapsed state. Because a new assembler is manufactured inside an existing assembler, reducing the volume occupied by the pressure equilibration subsystem in its compact state (i.e., the state in which it is manufactured) is advantageous. If the objective is to achieve the smallest manufactured size while simultaneously having the largest expanded size, manufacturing a collapsed sphere would seem to be the limiting case. A somewhat simpler system to manufacture in the collapsed state might be a tube. A tube is very compact when rolled up, much like a toothpaste tube after the toothpaste has been squeezed out or a rolled up sleeping bag. Inflating the tube (somewhat like a party blowout) would create a large increase in volume.

A second reason for keeping the external and internal pressures approximately the same is to reduce the changes in geometry caused by such pressure shifts. While mostly harmless, even relatively small shifts in geometry could influence the position of the tool holder with respect to the workpiece under construction. As this relative position must be maintained to within a fraction of an atomic diameter, the introduction of additional stresses on the positional mechanism and the mechanical path between it and the object under construction should normally be avoided.

We could have adopted a different approach. If, for example, we had decided on a vacuum for the internal environment, and had also decided to use external pressure changes to transmit information, we could have isolated the positional mechanism from the adverse affects of external pressure changes by introducing an external pressure shell decoupled from the internal mechanisms. The reader might note that we already have such an external shell, so it should be feasible to adopt this approach for the present design. The issue of geometry changes caused by external pressure changes when the new external pressure shell is itself being constructed would need to be addressed before this approach could be adopted, as well as the mechanisms for controlling the positional device and other internal devices when the pressure changes are not transmitted to the interior. While hardly insurmountable, these issues made the present approach appear somewhat simpler.

Other devices required for assembler operation besides the struts of the double tripod will also be operated by threshold pressure actuated ratchets. As will be appreciated, the use of the broadcast architecture and compressed neon as the broadcast medium for acoustic signals provides a great deal of flexibility in the positioning of mechanically operated control devices.

- To maintain the internal neon

environment while at the same

time preventing entry of contaminants requires a selective

transport mechanism for neon. Note that in this respect, the

use of neon requires a slightly more complex design

than helium. A selective transport mechanism for

helium would involve little more than small pores, large

enough in diameter to permit the passage of helium but

sufficiently small to exclude other contaminants. For

neon, a somewhat larger pore size will be required.

This larger pore size might permit the entry of linear

molecules composed of first row elements: e.g.,

N2, O2, CO2,

etc. A simple pore is therefore insufficient.

A mechanism for dealing with this problem

would be to (a) block both ends of the pore, (b) adopt a

short pore length, insufficient to hold any molecule

longer than neon in the pore when the ends are blocked

and (c) alternately open either end of

the pore. It is important that both ends of the pore never

be open at the same time, as this would permit entry of

linear molecules. Various mechanisms for achieving

this are possible. Drexler has proposed

a molecular pump which should be able to pump neon.

Hydrogen gas will likely be able to penetrate such a mechanism, and so hydrogen gas must be excluded from the external liquid -- suitable gettering should suffice. Helium will also be able to penetrate such pores. While the concentration of helium should be kept small, some trace amounts of helium should be harmless. Proposed designs for pores must be compared with the expected profile of contaminants in the surrounding liquid to insure that the rate of entry of contaminants is sufficiently small.

A few other small contaminants (such as N2) might also be of concern. While it seems unlikely that they would enter as readily as Ne, H2 or He, their entry rate might still be unacceptably high. If this proves to be the case, then their concentration in the external liquid environment must also be kept low. For the present proposal this is acceptable as a major objective is to simplify the design of the assembler even if that increases the cost of creating and maintaining the environment in which it operates. More generally, the complexity of the self replicating component can often be reduced by imposing tighter constraints on the environment in which it functions.

Many pore designs are possible. One approach would be to use buckytubes of suitably selected diameter. Particularly when we include helical bucky tubes, the range of possible diameters is very large and so the selection of an appropriate pore size should be relatively easy.

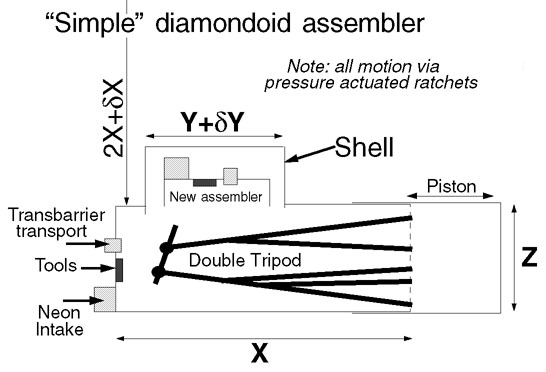

- Finally, self replicating systems that employ a barrier to prevent

external contaminants from entering the internal regions also require

a method of increasing the volume of the internal region.

We adopt a proposal by the author (described in

Nanosystems

along with several other approaches)

which has sometimes been called the replicating brick.

In this approach, a brick with dimensions X > Y > Z extrudes a new brick

along the Z axis oriented such that the Y dimension of the newly extruded

brick is aligned with the X dimension of the original brick, and the

Z dimension of the newly extruded brick is aligned with the Y dimension

of the original brick. The X dimension of the newly extruded brick is

aligned with the Z dimension of the original brick, but because this is

the direction of extrusion the fact that X > Z does not create a problem.

Rather than directly extruding a new brick of dimensions X, Y and Z; we will instead extrude a somewhat larger "hollow shell" of dimensions 2*X+deltaX, Y+deltaY, and Z+deltaZ. The hollow shell permits the construction inside it of two assemblers of dimensions X, Y and Z. When the two new assemblers have been manufactured inside the hollow shell, the shell is pushed out of the original assembler. This breaks the seal of the original assembler (the parent "dies" in the process of releasing the two offspring) and opens up one end of the hollow shell, thus permitting the two newly manufactured assemblers to exit the shell.

While this process is clearly wasteful (retaining the parent assembler in a functional state would be desirable), it simplifies the design of the extrusion process as the hollow shell is called upon to perform only a single task, rather than also acting as the wall of the new assemblers. Changes in the design of the hollow shell and its extrusion process have little impact on the design of the assembler.

The following diagram illustrates the main features:

Conclusions

We have briefly outlined an architecture for a self-replicating assembler able to synthesize the class of small diamondoid structures. While there is no obvious synthetic route to manufacturing this system with today's technology, it is significantly simpler than previous proposals. Further work aimed at defining more accessible proposals appears worthwhile. A series of proposals ranging from simple low performance systems that might be directly synthesized with today's technology to high performance systems able to make a wide range of diamondoid structures is needed, along with a clear description of how each proposed system would manufacture systems in the next stage of complexity and performance.References

- Brenner, D.W. (1990) Phys Rev B, 42 No. 15, November 15, pages 9458-9471. Empirical potential for hydrocarbons for use in simulating the chemical vapor deposition of diamond films

- Brenner, D.W.; Sinnott, S.B.; Harrison, J.A.; and Shenderova, O.A. (1996) Nanotechnology 7, pages 161-167. Simulated engineering of nanostructures

- Drexler, K.E. (1992) Nanosystems: Molecular Machinery, Manufacturing, and Computation, Wiley.

- Eigler, D.M. and Schweizer, E.K. (1990) Nature 344, pages 524-526. Positioning single atoms with a scanning tunnelling microscope

- Feynman, R.P. (1960) Caltech's Engineering and Science, February. There's Plenty of Room at the Bottom

- Merkle, R.C. (1992) Journal of the British Interplanetary Society, 45, pages 407-413. Self Replicating systems and molecular manufacturing

- Merkle, R.C. (1993) Chemical Design Automation News, 8, Nos. 9 & 10, September/October. Molecular Manufacturing: adding positional control to chemical synthesis

- Merkle, R.C. (1997a) Nanotechnology 8, pages 18-22. Convergent Assembly

- Merkle, R.C. (1997b) Nanotechnology 8, pages 23-28. Binding sites for use in a simple assembler

- Merkle, R.C. (1997c) Nanotechnology 8, pages 47-52. A new family of six degree of freedom positional devices

- Musgrave, C.B.; Perry, J.K.; Merkle, R.C.; and Goddard, W.A. (1991) Nanotechnology 2, pages 187-195. Theoretical studies of a hydrogen abstraction tool for nanotechnology

- Robertson, D.H.; Dunlap, B.I.; Brenner, D.W.; Mintmire J.W. and White, C.T. (1994) Materials Research Society Symposium Proceedings, 349, pages 283-288. Fullerene/tubule based hollow carbon nano-gears. See also http://chem.iupui.edu/Research/Robertson/Robertson.html.

- Sinnott, S.B.; Colton, R.J.; White, C.T.; and Brenner, D.W. (1994) Surface Science 316 pages L1055-L1060. Surface patterning by atomically-controlled chemical forces: molecular dynamics simulations

This

page is part of the

nanotechnology web site.

This

page is part of the

nanotechnology web site.